Wall Panels

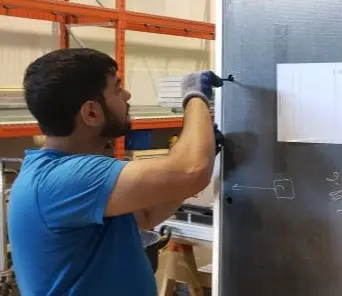

Structural Wall Panels features a high-strength fiberglass face sheet, recycled plastic foam core for insulation R10 and rigidity, a pultruded frame for strength and connectivity, reusable mechanical fasteners, and weather sealing for energy efficiency. Easy to install without specialized tools or skills.

Material: Fiberglass face sheets, Graphene-reinforced pultrusion frame, and recycled Armacell PET foam core

Dimensions:

Length: 2.43 m (8 ft.)

Width: 1.14 m (3.75 ft.)

Depth: 6.98 cm (2.75 inches)

Weight: 70 kg (154 lbs.)

Insulation Value: R10